3d print mold smooth

3D PRINT YOUR PARTS IN FEW SIMPLE STEPS. It works with PLA.

3d Printed Molds And Silicone Caulking Hackaday

3D Systems solutions developed for compatibility with jewelry mold making processes for high-volume manufacturing.

. The need to post finish is almost eliminated. FDM 3D printers are not entirely ineffective for jewelry making. Mold Star silicones cure to soft strong rubbers which are tear resistant and exhibit very low long term shrinkage.

Industrial FDM printing has a dimensional tolerance of 015 and a lower limit of 02 mm. We provide 3d cad design services all accross the globebring your product ideas in to reaility with our custom 3d design serviceswe also provide 3d desiggning and priinting service at one place. Fused deposition modeling FDM is one of the most common 3D printing processes and is often used to produce quick prototypes or functional parts.

Traditionally 3D printing focused on polymers for printing due to the ease of manufacturing and handling polymeric materials. Molds made with Mold Star will last a long time in your mold library and are good for casting wax gypsum resins and other materials. Check Price of Wood Filament on Amazon.

Wood print temperature range. 3D printed mold forms need to be smooth and non-porous before molding. Mold Star Series - Easy to Use Silicone Mold Rubber.

Inexpensive to Use 1 oz covers 100 square inches see coverage information below. Binder Jetting is a lesser known but versatile 3D printing technology which has applications in a variety of industries. And if high accuracy smooth surface finish are important requisites.

Trusted executive remuneration consultants our compensation and rewards strategies are engaged by leading organisations seeking to improve performance. Use it for décor ornate boxes tables and chairs figurines and whatever else catches the imagination. Injection Molding yields the lowest per-part cost.

Cured Mold Star rubber is heat resistant up to 450F 232C and is suitable for. 3D printing is also known as additive manufacturing therefore the numerous available 3D printing process tend to be additive in nature with a few key differences in the technologies and the materials used in this process. The need to post finish is almost eliminated.

3D Printing service is today mostly used for Mockup or Prototyping technical. Warping is one of the most common problems encountered in 3D printing and its one of the most annoying. 3D Printing Helps Jewelry Start-Up Vowsmith Ride the Mass Customization Wave.

What 3D print enthusiasts use wood filament for has no limits other than their creativity. Layer-by-layer fabrication of three-dimensional physical models is a modern concept that. Coat any 3D Print Surface - XTC-3D can be applied to both SLA and SLS prints.

They can still print forms for silicone molding material. Get Injection Mold. XTC3D fills in 3D print striations and creates a smooth high gloss finish.

Then use those molds with things like polymer or precious metal clays resins low-temperature metals and other castable materials. If youve ever seen the term ColorJet 3D printing. Metal 3D printing and in the printing of sand models and casts.

3DEXPERIENCE Make is an On-Demand Manufacturing platform which connects designers or engineers with industrial 3D Printing service providersOur service providers are mostly based in North America the United States and Canada and Europe United Kingdom France Netherlands Germany etc. Binder Jetting is similar to Selective Laser Sintering in that it requires powder on a build platform to 3D print. Our 3D jewelry printing solutions deliver parts with the high accuracy smooth finish.

3D print ultra-high-detail heat-resistant. 3D PRINT OR MANUFACTURE FROM OVER. It works with PLA ABS Laywoo Powder.

How To Make a Silicone Mold of a 3D Printed. But luckily it is easily preventable depending on your material and printing conditions there are different remedies well cover below. However the method has rapidly evolved to not only print various polymers but also metals and ceramics making 3D printing a versatile option for manufacturing.

Parts made with this sort of 3D printer often have smooth surfaces however the quality is highly dependent on the. 90 Time Labor Savings. XTC-3D fills in 3D print striations and creates a smooth high gloss finish.

A variety of processes equipment and materials are used in the production of a three-dimensional object via additive manufacturing. Is only for small quantities up to 10000000 pieces. Contains actual wood fibers.

XTC3D can be applied to both SLA and SLS prints. If youve used a 3D printer then its likely that youve experienced 3D print warping. FDM 3D printing creates objects by extruding thermoplastics through a heated nozzle.

Its used in two main areas.

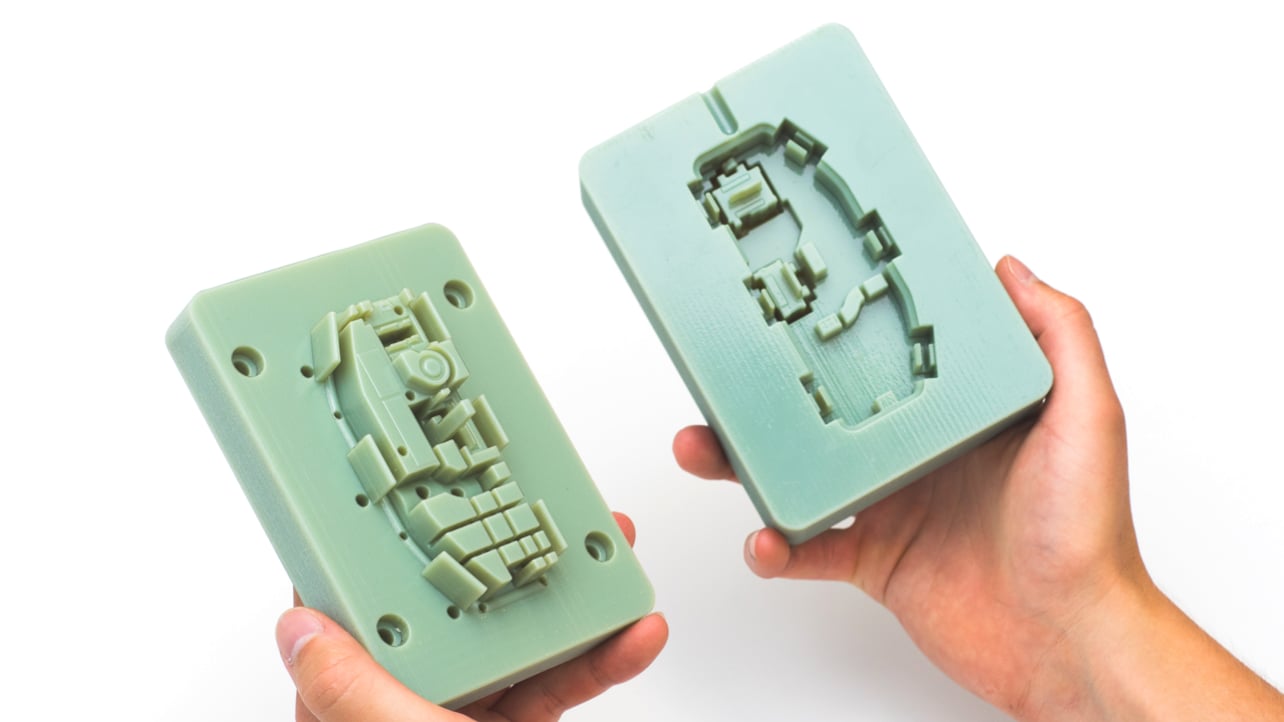

3d Printed Molds How To Get Started All3dp

Someone Asked A While Ago About Making Adult Toys With Their 3dp Used Pla For The Mold 0 1mm Layers And Smooth On Medium Firm Platinum Cure Silicone For The Casting With A

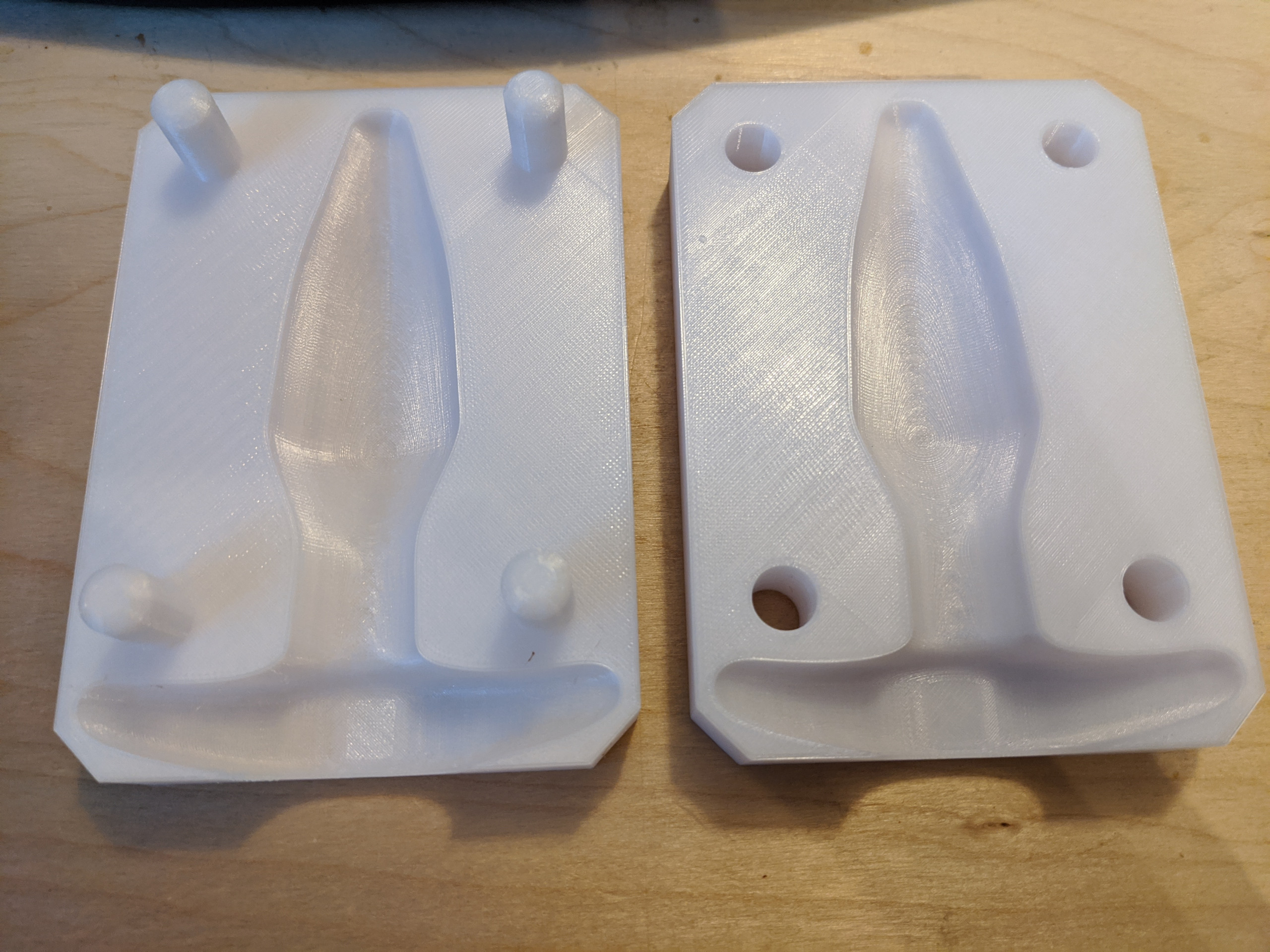

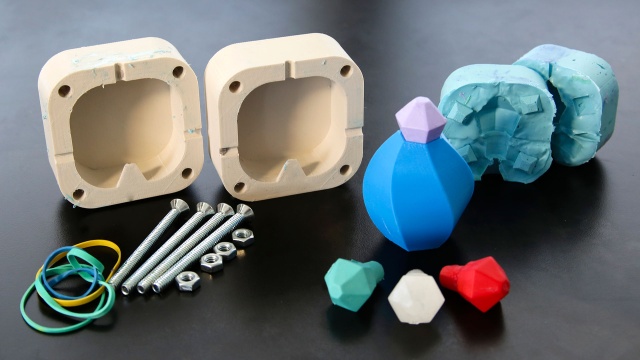

Learn How To Create A Two Part Silicone Mold From A 3d Print Matterhackers 3d Printing Diy 3d Printing Useful 3d Prints

3d Printing Of Soft Lithography Mold For Rapid Prototyping Of Download Scientific Diagram

Pla Smoothing How To Get Perfectly Smooth Pla 3d Prints Clever Creations

Resin And Silicone Casting With 3d Printed Molds Jason Webb

Ultimate Guide To Silicone Molding For 3d Printing Part 1 Makerbot 3d Printers

Silicone Casting With 3d Printed Moulds Dubious Creations

Pla Smoothing How To Get Perfectly Smooth Pla 3d Prints Clever Creations

3d Printed Molds With Silicone Rubber From Smooth On Food Safe Molds 2 Part Molds Youtube

How To Make A Silicone Mold Of A 3d Printed Part And Casting A Detailed Resin Training Skeleton

Casting Glass From 3d Printed Molds Amos Dudley

Silicone Molds From 3d Prints For The Love Of Learning

3d Printing Creates Molds For Uhpfrc Truss Structure Szolyd Concrete Corp

Xtc 3d Product Information Smooth On Inc

Learn How To Create A Basic Mold Using A 3d Printed Shape

Making A Platinum Silicone Mold Of An Sla Printed Uv Cure Model Youtube

Ultimate Guide To Silicone Molding For 3d Printing Part 1 Makerbot 3d Printers